Printed Circuit Board Assembly (PCBA) is a crucial step in the manufacturing process of electronic devices, where electronic components are mounted and soldered onto a printed circuit board (PCB) to create a functional electronic assembly. Let’s delve into the details:

Definition and Purpose

Definition

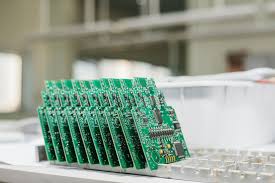

Printed Circuit Board Assembly (PCBA) refers to the process of populating a bare PCB with electronic components such as resistors, capacitors, integrated circuits (ICs), and connectors, followed by soldering the components onto the PCB to form a complete electronic assembly.

Purpose

The purpose of PCBA is to transform a bare PCB into a functional electronic device by assembling and soldering electronic components onto the board according to the design specifications and requirements.

PCBA Process Steps

Component Placement

The first step in PCBA involves placing electronic components onto the bare PCB according to the component placement plan generated from the PCB design files, typically using automated pick-and-place machines.

Solder Paste Application

Solder paste, a mixture of solder alloy particles and flux, is applied to the PCB’s pads using a stencil or dispenser, where the components will be soldered during the reflow soldering process.

Reflow Soldering

The PCB with components and solder paste is passed through a reflow soldering oven, where heat is applied to melt the solder paste, forming solder joints that electrically connect the components to the PCB.

Inspection and Testing

After soldering, the PCBA undergoes inspection and testing processes to detect and rectify any defects or faults, ensuring the quality, functionality, and reliability of the electronic assembly.

Rework and Repair

If defects are identified during inspection or testing, rework and repair processes may be performed to correct the issues, such as removing and replacing faulty components or repairing solder joints.

PCBA Technologies

Through-Hole Assembly

Traditional through-hole assembly involves inserting component leads through holes in the PCB and soldering them on the opposite side. It is suitable for components requiring strong mechanical support and high current-carrying capacity.

Surface Mount Technology (SMT)

Surface Mount Technology (SMT) involves mounting components directly onto the surface of the PCB, eliminating the need for holes and allowing for smaller, lighter, and more densely populated PCB assemblies.

Benefits of PCBA

Cost Efficiency

PCBA offers cost savings through automated assembly processes, reduced material waste, and improved production efficiency compared to manual assembly methods.

Quality Assurance

Automated inspection and testing processes in PCBA ensure consistent quality and reliability of electronic assemblies, reducing the risk of defects and failures.

Time Savings

PCBA accelerates production cycles and time-to-market for electronic devices by streamlining assembly processes and reducing lead times.

Design Flexibility

PCBA allows for design flexibility and customization, enabling rapid prototyping and iterative design improvements to meet evolving customer needs and market demands.

Conclusion

Printed Circuit Board Assembly (PCBA) is a critical stage in the manufacturing process of electronic devices, where electronic components are assembled and soldered onto a bare PCB to create functional electronic assemblies. By leveraging advanced assembly technologies and automated processes, PCBA offers cost efficiency, quality assurance, time savings, and design flexibility, driving innovation and advancement in the electronics industry. Learn more about printed circuit board assembly at printed circuit board assembly.